Values characterise the company

Companies that remain successful over many years are characterized by their own DNA; that something which makes them special and superior to other companies. At TROESTER, this DNA has been moulded through the company values: independence, courage, motivation to perform, readiness for innovation, trust, loyalty, sustainability, family and vision have made the company and its employees into what they are today. Our values shape the company and provide stability, not least in these times of new challenges.

Consistent values provide stability when they are acted upon. At TROESTER, these values are palpable. Troester is a family; the strong spirit behind this family forms the foundations on which economic success can flourish. The values represent a guarantee for retention of the company’s innate DNA, ensuring that the company can continue to prosper.

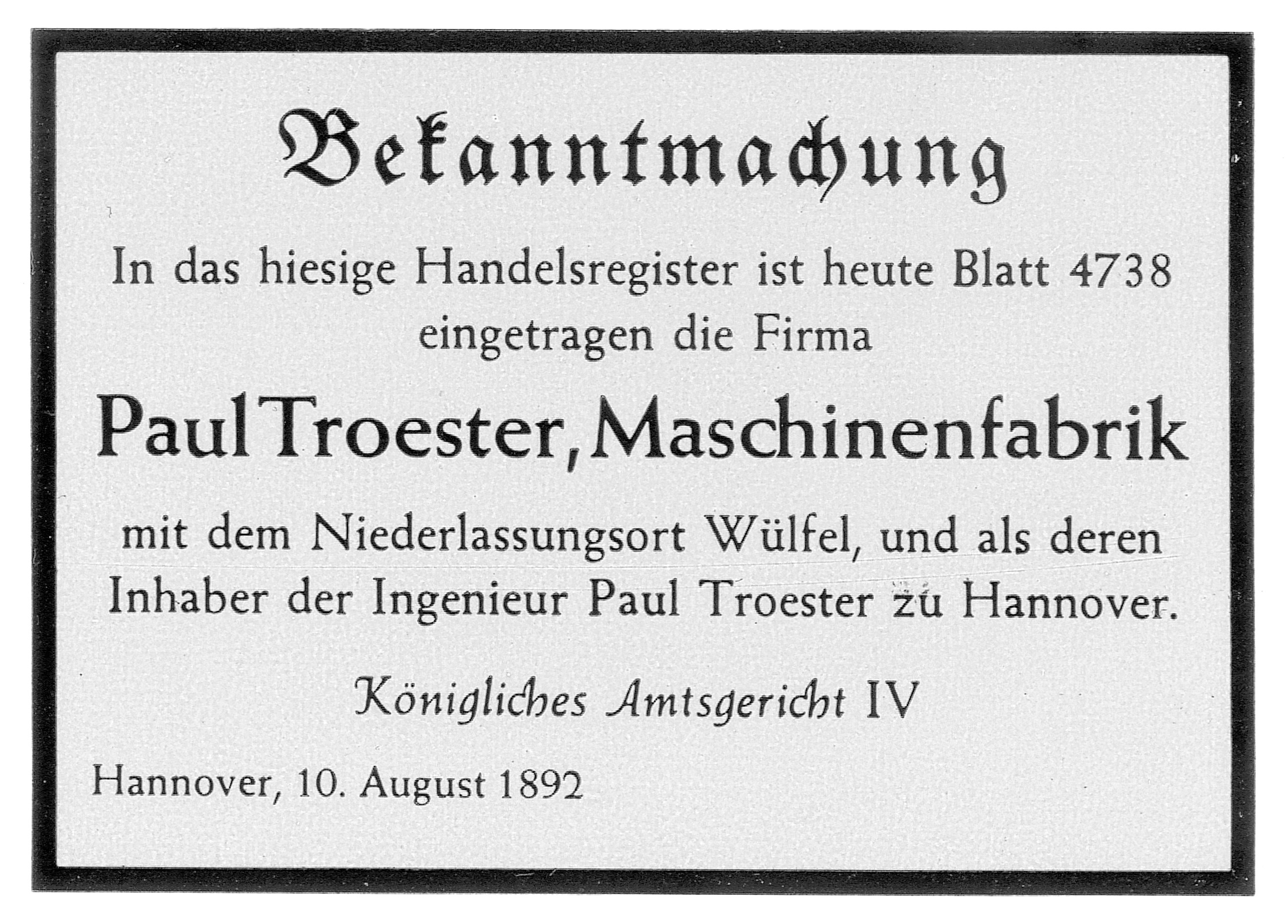

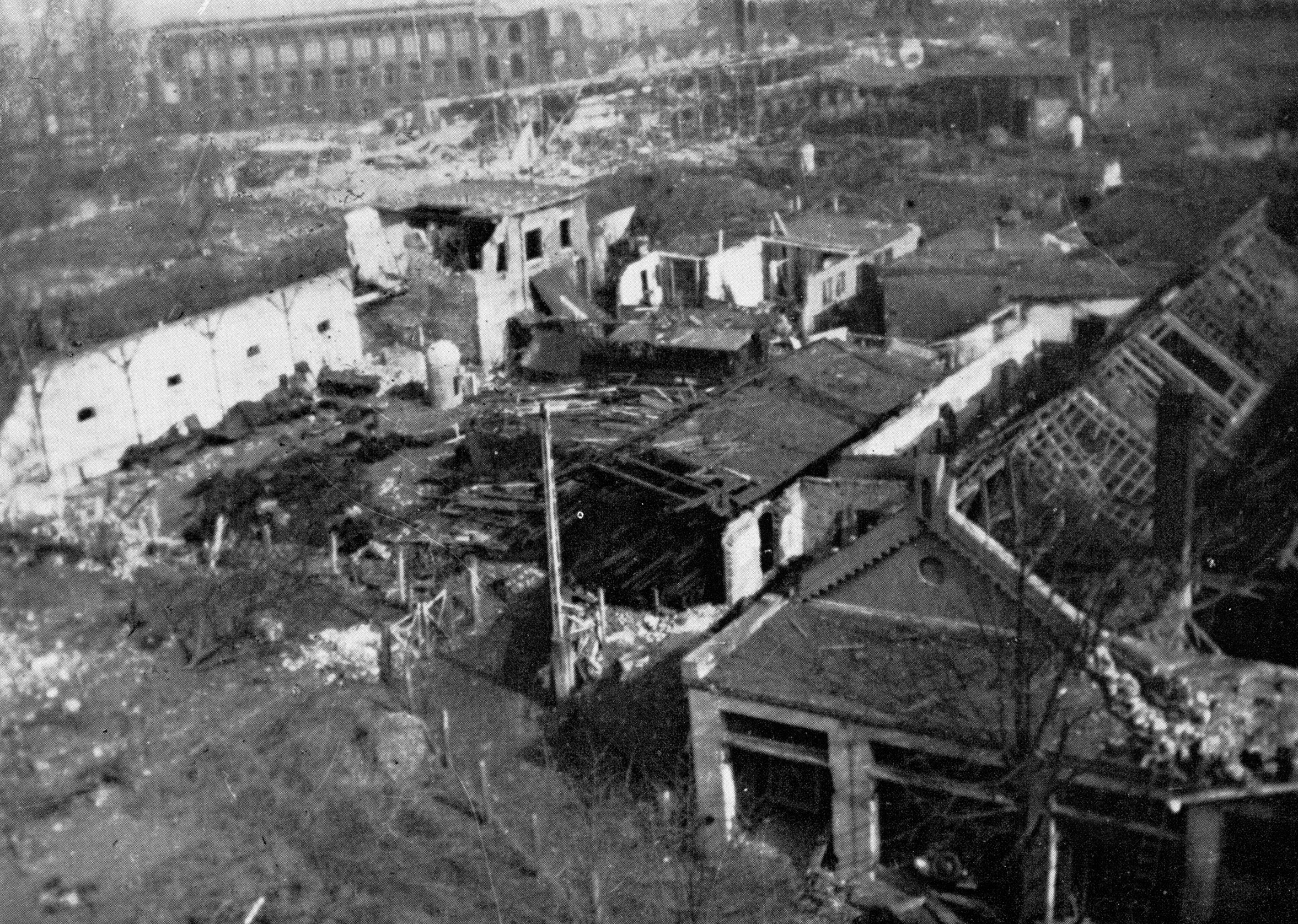

TROESTER is a success story, but none of the generations ever rested their laurels on the success of their predecessors. Troester is the result of hard work, of entrepreneurial spirit, and the readiness to strike off on new paths. The result is true excellence in what we do.