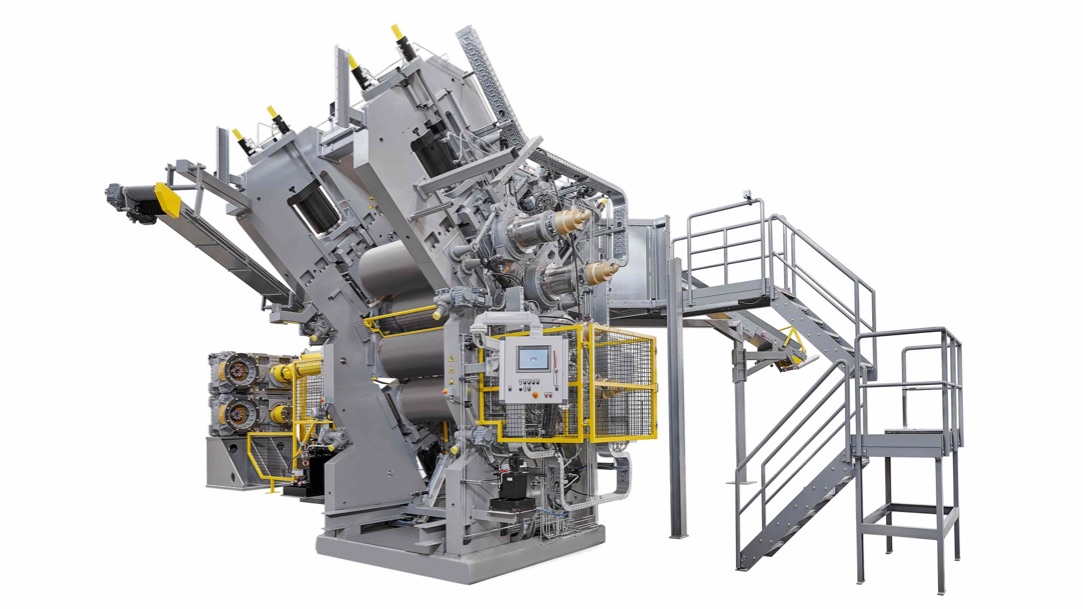

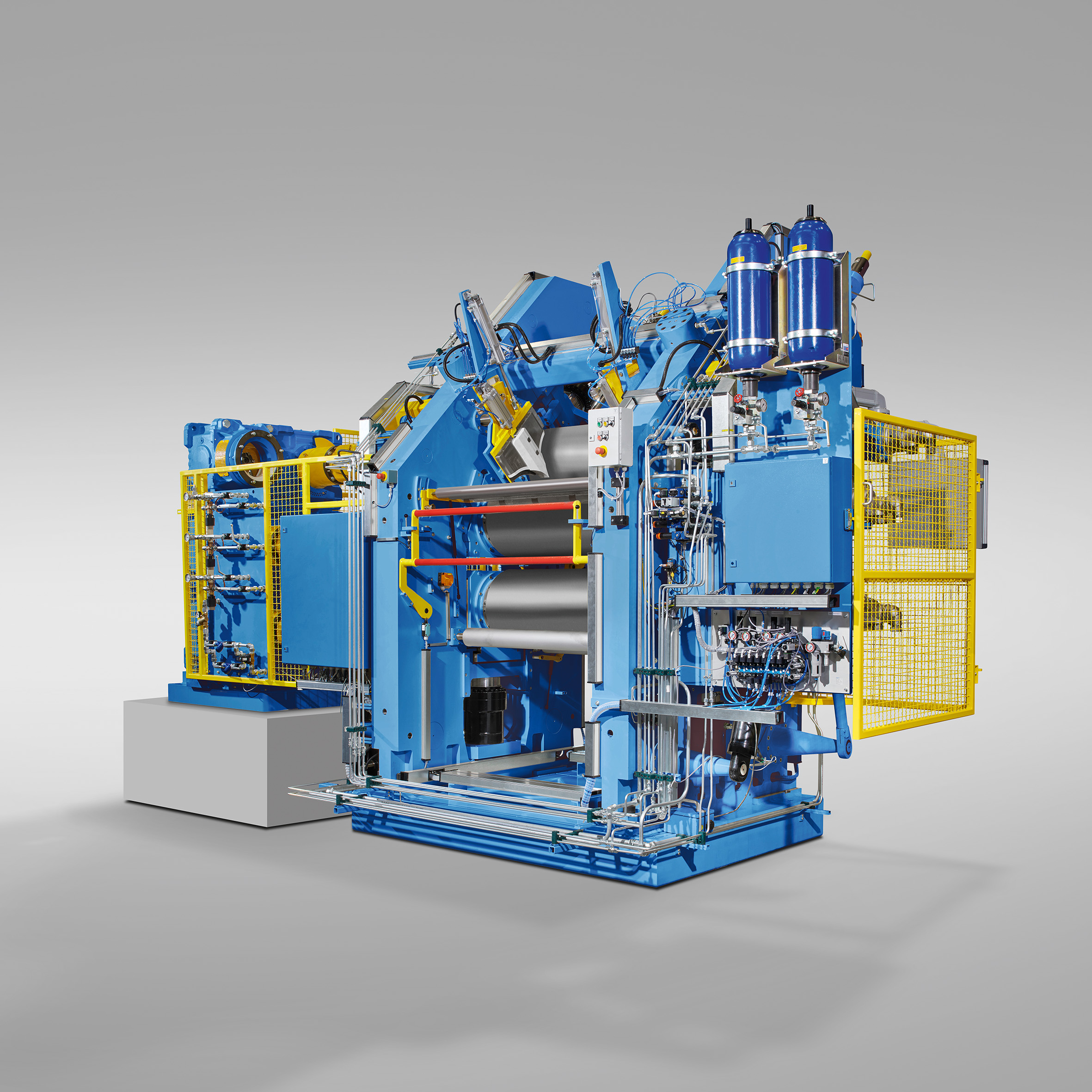

PRECISION IN RUBBER PROCESSING – CALENDERING SYSTEMS

TROESTER machines and lines for rubber processing stands for reliability, effectiveness, quality and innovation for over 130 years. Calendering technology plays an important role in the economic production of tightly tolerated, high-quality rubber sheets – individually, as part of a complete system or combined as a hybrid with other technologies.

Highlights

-

Suitable for thin, parallel products

-

Multi roll calenders

-

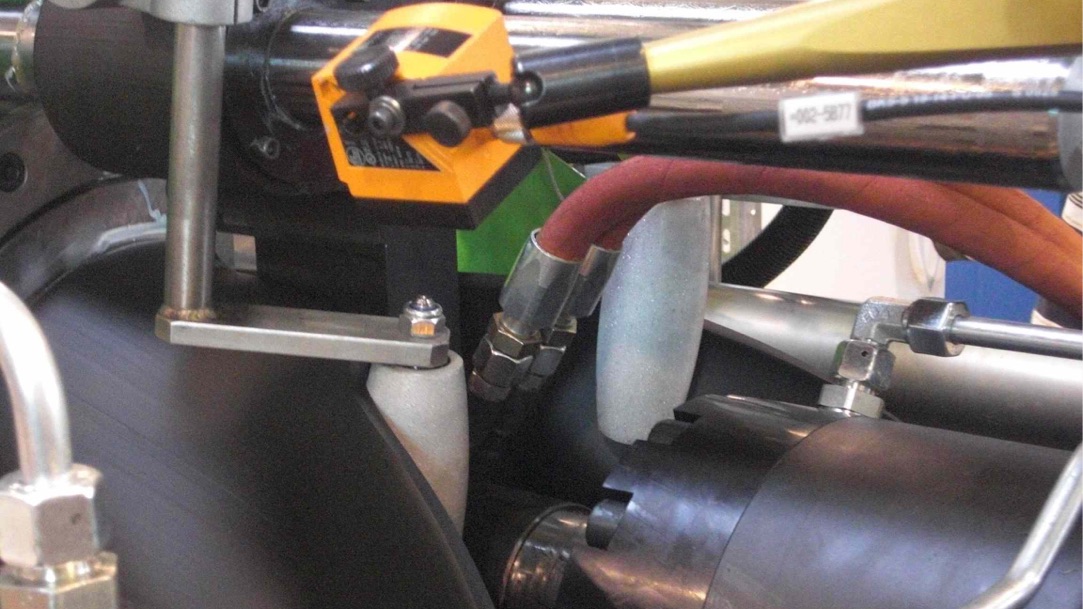

Characteristics rolls technology

-

Calender System at a Glance

Downloads

-

calender systems

- 1.3MB

Contact us

-

![Troester 181011 0925-0926]()

Mr. Karsten Jung

Director Sales Rubber