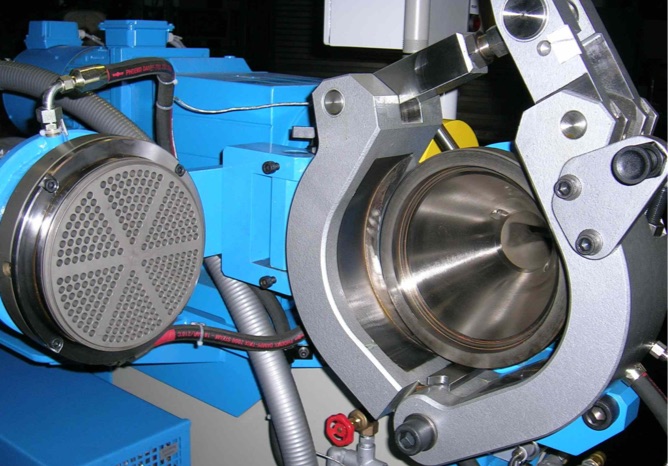

ROTOMEX

TROESTER’s ROTOMEX is a compact and energy-efficient gear extruder designed for straining of different rubber compounds. Operating on the principle of a gear pump with integrated feed gears. With optional vacuum degassing and precise temperature control ROTOMEX enables effective pre-heating and low-temperature plasticisation. Compared to traditional single-screw extruders, it offers up to 70% energy savings and minimises thermal stress on the compound.

Highlights

-

Stand alone machines

-

ADVANTAGES

Downloads

-

Gear Extruders

- 2MB

Contact us

-

![gear-extruder]()

Mr. Karsten Jung

Director Sales Rubber