PRECISION IN RUBBER PROCESSING – SINGLE-ROLL ROLLER DIE SYSTEMS

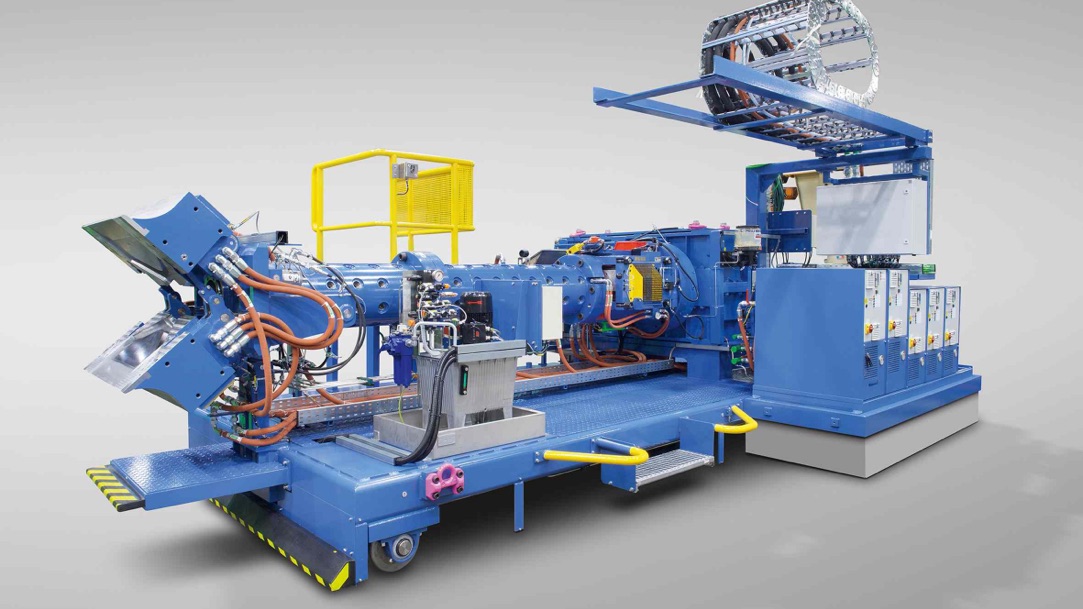

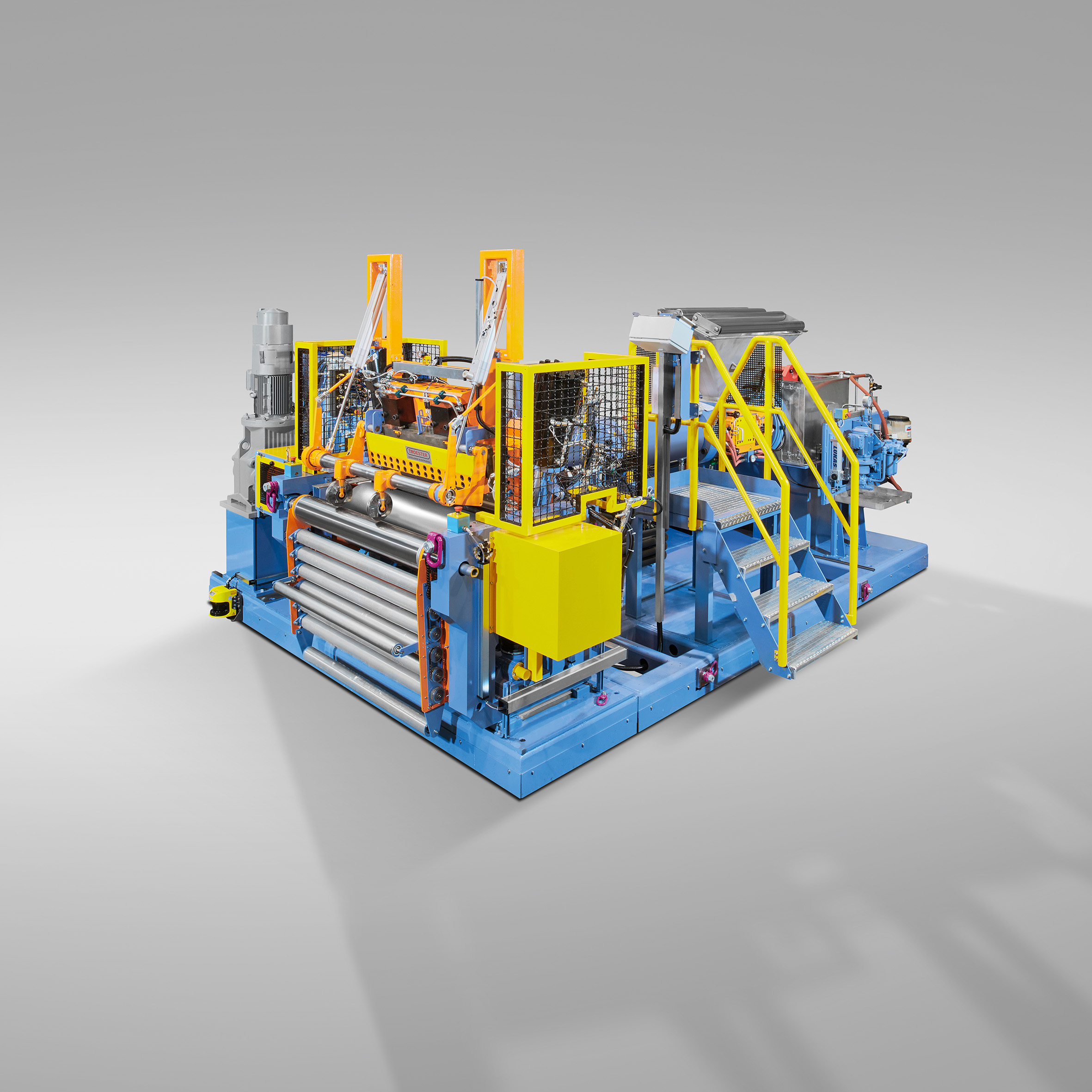

The Single-Roll Roller Die can be used to produce high-quality profiled rubber sheets in different widths and thicknesses, such as, for example, sidewalls for automobile tires, rim strips, profile strips (also with undercut and highly sensitive, thin wall sections), treads, apex strips, inner liners and rubber sheets.

Highlights

-

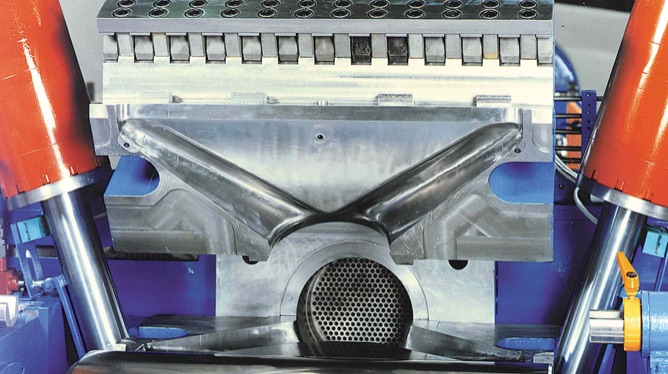

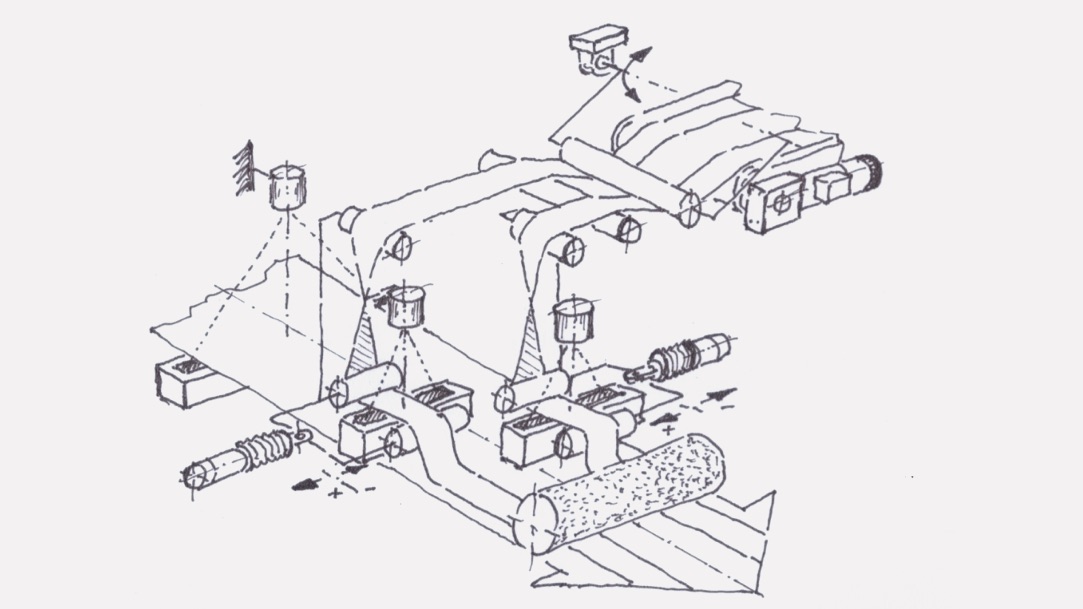

The single-roll roller die systems consists of three main parts

-

Suitable for flat-bottom profiles

-

Adaptable for different applications

-

Process advantages

Downloads

-

Single roll roller die systems

- 3MB

Contact us

-

![Troester 181017 0960]()

Mr. Karsten Jung

Director Sales Rubber